|

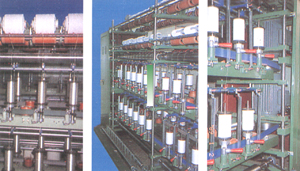

- The spindle bracket with Iron Cast can be extended of life and keep a stable level.

- The guide roller is designed for preventing the contamination of Yarn's from dust.

|

|

- Cradle Stopper installed

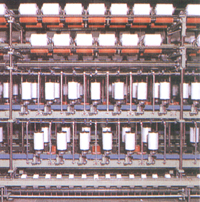

- Special spindles are arranged to maintain equal loads and rotations of the upper and lower motors, and various angles and casting brackets are attached to ensure high-speed rotation.

|

|

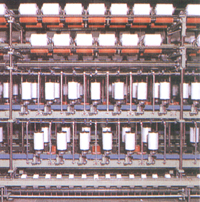

- Bobbins with bigger quantity are employed to reduce the numbers of yarn knots and are intended to be replaced every two days to minimize the contamination of yarn, so that great effect to labor cost saving can be obtained.

|

|

- Well-desingned Cradle for maximum winding of yarn and good condition of winding.

|

|

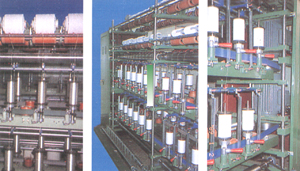

- Production process of polyestrer spun yarn.

|

|

- New high-speed covering machine

(Direct Driving Type)

|